Grinton lead smelt mill.

N.B. Narrative and pictures are as of the times when the pictures were originally added (mostly 1997 to

2004). In 2021, things may look different; conditions, tracks and rights of way may have changed.

Click on the Home button for more explanation.

In mid June 1998, John Archbold, Rod Ayres and Robin Johnstone, made a trip into "the

Dales" with a mission to seek out the Grinton and also the Cobscar lead smelt mills. The day

was fine without being hot so the conditions were at their best for walking on the moorland.

How we got there.

At Grinton in Swaledale, we headed for Leyburn to the South-East. After only about a mile,

the road turns left at a bridge over Cogden Beck. Just after this, on our right, was a wide

opening. That is where we parked. The smelt mill came into view after only a short walk.

Around the mill.

We found the Grinton site to be the best Dales'

site to visit to gain an understanding of the

functions of a lead smeltery complex. The smelt

mill itself is the best preserved. There is a

preserved peat store. There is a flue built on the

hillside. The earthworks for dams are still evident

in the valley.

Shown at right, is part of the now incomplete flue.

Like the smelter and peat store, it has been

preserved. The picture shows that mortar has

been used to point the broken ends and so halt the

disintegration. The flue drew the fumes from the

smelter. The poisonous and corrosive gases were

expelled at a square vertical chimney sited on the

moor top. Only the foundations of the verrtical

chimney remain. There was some residual lead in

the fumes which left the hearths. Much of this

residual lead was deposited on the flue's surfaces

and could be rccovered by sweeping the flue.

After leaving the smelt mill (bottom building), the

flue followed the wall of the peat store (edge-on

building). Presumably this arrangement would

have warmed the wall and could have helped to

keep the peat dry. In the first picture on this page,

the position once occupied by the flue along the

peat store can be seen (where the stone is a lighter

colour).

One of the many access and inspection hatches in the flue.

In this picture, John is seen standing by Bolton

Gill. It would have been the suitability of the

gill to provide water power, which would have

decided the original siting of the complex. The

smelt mill is the nearer building. The missing

part of the flue would, after it left the smelter,

have gone upwards to skirt the far side of the

peat store on the left of the picture. Then it

would have met the piece of flue pictured in

this page.

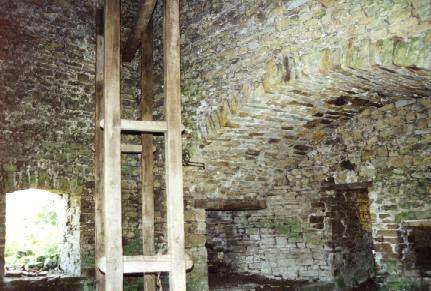

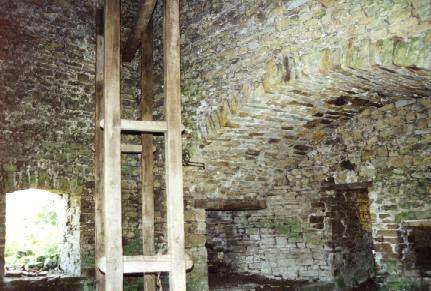

Inside Grinton Mill.

Grinton Mill stands by Cogden Beck. Water from higher up

the beck was once led in an overhead aqueduct to an overshot water wheel inside the smelt

mill. The wheel has gone. The wheel would have driven the blower forcing the fires in the

smelting hearths. The support frame for the blower was still in place. The mill holds the

crown for being the best preserved of the Dales' lead smelt mills. The sites of two of the three

hearths are still well defined in the mill. The Dales Mines Preservation Society has put a lot of

effort into restoring and pointing. Shown below are the remains of an ore hearth (left of

picture) showing the entry to the internal part of the flue (top of picture).

The upright frame

shown in pictures,

had led Arthur

Raistrick to suggest

that the blower for

the hearths had at

some time been a

patented system such

as a Vaughan's

Blower, a large

upright cylindrical air

pump. However,

subsequent opinion was that this was never the case but

that bellows were used to blow the hearths.

At left, the overhead launder which carried the

water into the smelter to work the overshot water

wheel.

Returning to the outside.

The launder entry seen from outside the building.

It looks as though the water supply (to the water

wheel which worked the smelter's blower) was

channelled here. The water had to be channelled

from higher up Cogden Beck and enter at height

to work the overshot wheel. The depression, at

the back of the peat house, turns to your right

and lines up with the launder entry point in the

mill wall opposite.

There is a wealth of evidence of former earthworks around Grinton smelter. From the east

side of the valley, you can see earthworks and dams.

Areas still wet enough to support stands of

reeds suggest sites of former reservoirs.

A vertical shaft into the ground near the large dam.

When we discovered this in Summer 2000, we were

mystified as to its purpose and assumed it had ventilated

Devis Hole mine in the vicinity. Barry Jones

subsequently gave us the true answer. The original

entrance to Devis is collapsed and the shaft pictured here

had been created recently and is used to access and

research the

mine.

There are many ancient workings to be seen on the

moor top to the west of Grinton Mill. A particularly

regularly defined raised lip, on which John is seen

sitting, surrounds this working on the moor-top. We

thought it was possibly the surface remains of an old

bell pit which had in typical fashion collapsed.

Link to the page on the Keldside Smelt Mill >>>

Grinton

lead smelt mill.

N.B. Narrative and pictures are as of the times when

the pictures were originally added (mostly 1997 to

2004). In 2021, things may look different; conditions,

tracks and rights of way may have changed.

Click on the Home button for more explanation.

In mid June 1998, we that is John Archbold,

Rod Ayres and Robin Johnstone, made a trip

into "the Dales" with a mission to seek out the

Grinton and also the Cobscar lead smelt mills.

The day was fine without being hot so the

conditions were at their best for walking on

the moorland.

How we got to the Grinton smelt mills.

At Grinton in Swaledale, head for Leyburn to the

South-East. After only about a mile, the road

turns left at a bridge over Cogden Beck. Just

after this, on your right, is a wide opening. That

is where we parked. The smelt mill comes into

view after only a short walk.

Around the mill.

We found the Grinton site to be the best Dales'

site to visit to gain an understanding of the

functions of a lead smeltery complex. The smelt

mill itself is the best preserved. There is a

preserved peat store. There is a flue built on the

hillside. The earthworks for dams are still evident

in the valley.

Shown below, is part of the now incomplete flue.

Like the smelter and peat store, it has been

preserved. The picture shows that mortar has

been used to point the broken ends and so halt

the disintegration. The flue drew the fumes from

the smelter. The poisonous and corrosive gases

were expelled at a square vertical chimney sited

on the moor top. Only the foundations of the

chimney remain.

There was some residual lead in the fumes which

left the hearths. Much of this residual lead was

deposited on the flue's surfaces and could be

rccovered by sweeping the flue. After leaving the

smelt mill (bottom building), the flue followed

the wall of the peat store (edge-on building).

Presumably this arrangement would have

warmed the wall and could have helped to keep

the peat dry. In the first picture on this page, the

position once occupied by the flue along the peat

store can be seen (where the stone is a lighter

colour).

The picture here

shows one of the many

access and inspection

hatches in the flue.

In the picture below, John is seen standing by

Bolton Gill.

It would have been the suitability of the gill to

provide water power, which would have decided

the original siting of the complex. The smelt mill

is the nearer building. The missing part of the

flue would, after it left the smelter, have gone

upwards to skirt the far side of the peat store on

the left of the picture. Then it would have met the

piece of flue pictured in this page.

Inside Grinton Mill.

Grinton Mill stands by Cogden Beck. Water from

higher up the beck was once led in an overhead

aqueduct to an overshot water wheel inside the

smelt mill. The wheel has gone. The wheel

would have driven the blower forcing the fires in

the smelting hearths. The support frame for the

blower was still in place. The mill holds the

crown for being the best preserved of the Dales'

lead smelt mills. The sites of two of the three

hearths are still well defined in the mill.

The Dales Mines Preservation Society has put a

lot of effort into restoring and pointing.

Shown below are the remains of an ore hearth

(left of picture) showing the entry to the internal

part of the flue (top of picture).

The upright frame shown in pictures below, led

Arthur Raistrick to suggest that the blower for

the hearths had at

some time been a

patented system

such as a

Vaughan's Blower,

a large upright

cylindrical air

pump.

However, the

subsequent belief

was that this was

never the case but

that bellows were

used to blow the

hearths.

Below: The overhead launder which carried the

water into the smelter to work the overshot water

wheel.

The launder entry seen from outside the building.

Returning to the outside.

It looks as though the water supply (to the water

wheel which worked the smelter's blower) was

channelled here. The water had to be channelled

from higher up Cogden Beck and enter at height

to work the overshot wheel. The depression, at

the back of the peat house, turns to your right and

lines up with the launder entry point in the mill

wall opposite.

There is a wealth of evidence of former

earthworks

around Grinton

smelter. From

the east side of

the valley, you

can see

earthworks and

dams. Some

areas are still

wet enough to

support stands of reeds, suggesting that they

were once the sites of reservoirs.

A vertical shaft near the large dam.

When we came across this in Summer 2000, we

were mystified as to its purpose and assumed it

had ventilated Devis Hole mine in the vicinity.

Barry Jones put us right on this. The original

entrance to Devis is collapsed and the shaft

pictured here had been created recently and is

used to access and research the mine.There are

many ancient workings to be seen on the moor

top to the west of Grinton Mill.

A particularly regularly defined raised lip, on

which John is sitting in this picture, surrounds

this working on the moor-top. It looks like it is

the surface remains of an early bell pit, which

has collapsed.

Link to the page on the

Keldside Smelt Mill >>>