Cobscar smelt mill, Wensleydale.

N.B. Narrative and pictures are as of the times when the pictures were originally added (mostly 1997 to 2004).

In 2021, things may look different; conditions, tracks and rights of way may have changed.

Click on the Home button for more explanation.

To get from Swaledale to the take the road

South from Grinton in Swaledale, heading for

Castle Bolton. After 2 1/2 miles (4 km.), the

road goes left (at a point where a right turn

heads towards Apedale). After only another

1/2 mile, the road turns right. Find a place to

park. If it is a clear day, look around in the

valley to the South and you will see Castle Bolton.

On the inside of the corner (as if you had gone straight on) is a gate. Go though it and follow a road.

You will soon see Cobscar's chimney cominginto view from behind a hill on your left. Note also,

Cobscar Rake on your left. It is clearly defined even now as disturbed ground and stones, about

2 miles long.

We understand that Cobscar lead smelter (smelt mill) had four hearths. Firstly, the ore was heated

in the roasting hearth to scrub out a lot of the sulphur before the smelt. Then, the roasted ore was

passed on to the two ore hearths which did the major part of the smelt. The grey slag from these was

transferred to the single slag hearth to recover even more lead from the slag.

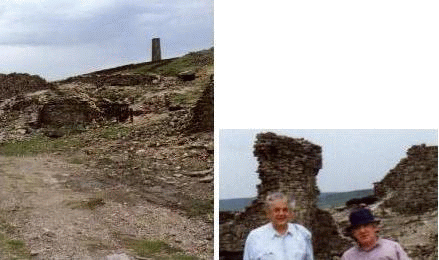

Pictures: Broken flue and the chimney.

Cobscar Lead Smelt Mill, up to sometime a little before the middle of the 20th Century, was still in

good condition, with most of the machinery still in place. It had the potential to be one of today's

best monuments to the Yorkshire Dales lead industry. The area was once used for military training.

There is still a military training area nearby. Arthur raistrick reports that, sadly, the smelt mill was

destroyed in demolition practice. Today, only Cobscar's square chimney is anywhere near intact.

The Cobscar chimney was at one time shared by another flue, that from the Keld Heads smelter,

about a kilometre away. The flue from Keld Heads can be seen as a diagonal strip on the moor,

near the right of the inset. On the day of our visit, we noticed that the side of the chimney facing the

smelter has now got diagonal damage which looks like the result of a lightning strike. Was this

damage recent and would it cause the demise of the chimney? A picture taken in 1974 (not shown

here) and showing that side of the chimney, was reassuring. The damage was already evident then

and the chimney had stood another 24 years since.

The Cobscar Rake. What's in a name?

The Cobscar Rake, mentioned earler above, is a long and fascinating surface feature with one end

terminating near the Cobscar Smelter. The Cobscar "Rake," in common with other "Rakes" in the

area has an appearance as though the land has been raked over with a gigantic rake. We mused as

to whether the name "Rake" resulted from this appearance.

The Cobscar Rake Vein connected to a group of veins further West, called Walker Wife Vein and

Bolton Park Vein, in Bolton Gill and Apedale. Inevitably, ore in outcrops was the first to be exploited.

It is likely that in common with other places where veins outcropped as at Old Rake, at Old Gang and

at Chaytor Rake, the vein at Cobscar Rake would have been exploited long ago, perhaps as far back

as 2000 years ago during the Roman occupation of Britain. In the earliest days, the ore near the

outcrops could have been exposed by removing the surface along the seam to expose the ore to the

hammers and picks of the prospectors. Pits would have then have been dug to continue the

exploitiation of the Cobscar Rake Vein when the outcrops had been harvested.

There is a succession of pits along the Cobscar Rake.

Some Ah Buts (see “Home” page): Below is some history derived from Arthur Raistrick:

The Chaytor family was involved in lead mining in this area in the Eighteenth Century with leases

including the Cobscar and Chaytor Rakes.

Cobscar Mill may have been built around 1752 for William Chaytor, at the East end of the Cobscar

Rake. Arthur Raistrick reported that The Chaytor family appear to have held the leases throughout

the life of the Cobscar lead smelter. It probably smelted for the Cobscar Rake itself and Cranehow

Bottom Mine, about a kilometre North East of the mill, on the Chaytor Rake.

Cobscar lead smelter was probably shut down in or after 1857.

Link to the page on the Grinton Smelt Mill >>>

Cobscar

Smelt

Mill

N.B. Narrative and pictures are as of the times when

the pictures were originally added (mostly 1997 to

2004). In 2021, things may look different; conditions,

tracks and rights of way may have changed.

Click on the Home button for more explanation.

To get from Swaledale to the Cobscar Smelt

Mill, take the road South from Grinton in

Swaledale, heading for Castle Bolton.

After 2 1/2 miles (4 km.), the road goes left (at

a point where a right turn heads towards

Apedale). After only another 1/2 mile, the road

turns right. Find a place to park up. If it is a

clear day, look around in the valley to the

South and you will see Castle Bolton.

On the inside of the corner (as if you had gone

straight on) is a gate. Go though it and follow a

road. You will soon see Cobscar's chimney

coming into view from behind a hill on your

left. Note also, Cobscar Rake on your left. It is

clearly defined even now as disturbed ground

and stones, about 2 miles long.

We understand that Cobscar lead smelter had

four hearths. Firstly, the ore was heated in the

roasting hearth to scrub out a lot of the

sulphur before the smelt. Then, the roasted ore

was passed on to the two ore hearths which did

the major part of the smelt. The grey slag from

these was transferred to the single slag hearth

to recover even more lead from the slag.

Broken flue and chimney.

Cobscar Lead Smelt Mill, up to sometime a

little before the middle of the 20th Century,

was still in good condition, with most of the

machinery still in place. It had the potential to

be one of today's best monuments to the

Yorkshire Dales lead industry. The area was

once used for military training. There is still a

military training area nearby. Arthur raistrick

reports that, sadly, the smelt mill was

destroyed in demolition practice. Today, only

Cobscar's square chimney is anywhere near

intact. The Cobscar chimney was at one time

shared by another flue, that from the Keld

Heads smelter, about a kilometre away. The

flue from Keld Heads can be seen as a diagonal

strip on the moor, near the right of the inset.

On the day of our visit, we noticed that the side

of the chimney facing the smelter has now got

diagonal damage which looks like the result of

a lightning strike. Was this damage recent and

would it cause the demise of the chimney? A

picture taken in 1974 (not shown here) and

showing that side of the chimney, was

reassuring. The damage was already evident

then and the chimney had stood another 24

years since. The Cobscar Rake. What's in a

name?.

The Cobscar Rake is a long and fascinating

surface feature with one end terminating near

the Cobscar Smelter. The Cobscar "Rake," in

common with other "Rakes" in the area has an

appearance as though the land has been raked

over with a gigantic rake. We mused as to

whether the name "Rake" resulted from this

appearance.

The Cobscar Rake Vein connected to a group

of veins further West, called Walker Wife Vein

and Bolton Park Vein, in Bolton Gill and

Apedale. Inevitably, ore in outcrops was the

first to be exploited. It is likely that in common

with other places where veins outcropped as at

Old Rake, at Old Gang and at Chaytor Rake,

the vein at Cobscar Rake would have been

exploited long ago, perhaps as far back as 2000

years ago during the Roman occupation of

Britain. In the earliest days, the ore near the

outcrops could have been exposed by removing

the surface along the seam to expose the ore to

the hammers and picks of the prospectors. Pits

would have then have been dug to continue the

exploitiation of the Cobscar Rake Vein when

the outcrops had been harvested. There is a

succession of pits along the Cobscar Rake.

Some Ah Buts: Some history derived from

Arthur Raistrick:

The Chaytor family was involved in lead

mining in this area in the Eighteenth Century

with leases including the Cobscar and Chaytor

Rakes.

Cobscar Mill may have been built around 1752

for William Chaytor, at the East end of the

Cobscar Rake. Arthur Raistrick reported that

The Chaytor family appear to have held the

leases throughout the life of the Cobscar lead

smelter. It probably smelted for the Cobscar

Rake itself and Cranehow Bottom Mine, about

a kilometre North East of the mill, on the

Chaytor Rake.

Cobscar lead smelter was probably shut down

in or after 1857.

Link to the page on the Grinton Smelt Mill

>>>